SEMICONDUCTOR

Semiconductor and EUV-Lithography

Increasing throughput. Smaller and smaller structures. More and more cost-effective microchips. BERGHOFF meets the extremely stringent requirements for the mechanical components.

Welcome to BERGHOFF

Welcome to BERGHOFF

Über 40 Jahre Präzision aus Leidenschaft

For more than 35 years, leading high-tech companies from the mechanical and plant engineering sector have trusted BERGHOFF with the planning and production of highly complex components, assemblies and modules. We meet your very highest demands on quality and security of supply and support you as a strategic partner to further expand your top position and technology leadership in your market.

It is our conviction that a machine can only be produced in outstanding quality if every single component fulfills this requirement. To this end, we contribute the know-how of the world's best manufacturing specialists and our state-of-the-art machinery on a daily basis. Reliably and on time, in thousands of successful projects.

In addition to our operational excellence, we see ourselves first and foremost as the supply chain partner for complete mechanical solutions in our customers' value chain. We implement your ideas flexibly and innovatively from project planning to the finished component reliably into reality. Everything from a single source. As a result, we realize significant economies of scale for you.

Highest reliability and flexibility

Top-trained and experienced employees ensure the highest process and machining quality. Our powerful state-of-the-art machinery offers best-in-class conditions such as air conditioning and state-of-the-art testing and cleaning procedures.

BERGHOFF achieves manufacturing tolerances of the highest precision. Prototypes and customized special projects are realized agilely in less than 4 weeks.

Everything from one source

On request, our customers can obtain all the relevant steps in their value chain from a single source, in addition to production. These include, for example, material procurement, a wide range of services such as electron beam welding, vacuum brazing or special surface finishing, cleaning and complete assembly.

Significant cost savings and quality improvements are regularly realized in the process.

We guarantee full transparency for our customers: They know at all times and at every step how and where their product is processed.

Innovation and technological progress

We are constantly working to further expand the technological leadership of our customers.

The introduction of highly innovative technologies and processes as well as the constant review and improvement of all machining processes is an integral part of our work.

The result is continuous optimization at all production levels. We pass on the knowledge gained from this to our customers.

Seit über 35 Jahren vertrauen führende Hightech-Unternehmen aus dem Maschinen- und Anlagenbau der BERGHOFF bei der Planung und Fertigung hochkomplexer Bauteile, Baugruppen und Module. Wir erfüllen Ihre very highest demands on quality and security of supply and support you as a strategic partner to further expand your top position and technology leadership in your market.

It is our conviction that a machine can only be produced in outstanding quality if each individual component also meets this requirement. To achieve this, we use the know-how of the world's best manufacturing specialists and our state-of-the-art machinery. Reliably and on time, in thousands of successful projects.

In addition to our operational excellence, we see ourselves above all as the supply chain partner for complete mechanical solutions in our customers' value chains. We reliably turn their ideas into reality in a flexible and innovative von der Entwicklung bis zur fertigen Komponente zuverlässig in die Realität um, all from a single source. As a result, we realize significant economies of scale for them.

Unser klimatisierter Reinraum nach ISO-6-Sauberkeitsstandard steht kurz vor der Inbetriebnahme und ermöglicht die reinraumgerechte Montage von Baugruppen sowie die Weiterverarbeitung komplexer Bauteile bis hin zu Modulen. Darüber hinaus bieten wir Reinigungs- sowie Qualifizierungsdienstleistungen nach kundenspezifischen Vorgaben an.

Wir setzen für unsere Kunden mit unserer Ultraschallreinigung, der Vakuumentgasung (Bake-Out) sowie der Reinigungszelle für Großbauteile modernste Nass- und Trockenreinigungsverfahren ein.

Ergänzend führen wir Restgasanalysen zur Qualifizierung oder Helium-Lecktests zur Dichtheitsprüfung von Bauteilen und Baugruppen durch.

Damit decken wir die komplette Wertschöpfungskette ab – von der Fertigung einzelner Komponenten über Reinigung und Qualifikation bis hin zur reinraumgerechten Verpackung und montagefertigen Lieferung komplexer Schlüsselkomponenten und Modulen in die Reinräume unserer Kunden.

Mit unserem künftig bereitstehenden Reinraum schaffen wir eine Umgebung, die besonders kontrollierte Bedingungen für anspruchsvolle Montage- und Qualifizierungsprozesse ermöglicht. Temperatur, Feuchtigkeit und Luftführung werden dabei so stabil gehalten, dass selbst sensible Baugruppen reproduzierbar und mit gleichbleibender Präzision verarbeitet werden können.

Strenge Sauberkeitsstandards sichern die Produktqualität und Prozessstabilität, wodurch BERGHOFF die hohen Anforderungen der Kunden gewährleistet. Klare Materialflüsse und definierte Prüfschritte unterstützen zusätzlich eine durchgängige Rückverfolgbarkeit – ein wichtiger Beitrag zur Sicherheit jeder einzelnen Prozessstufe.

BERGHOFF's strategic partners typically come from highly demanding industries and are looking for a premium supplier. BERGHOFF customers are characterized by above-average demands on process quality, processing quality, security of supply and communication processes in particular.

It is precisely the greatest possible reduction of supply risk that has top priority with our customers and is one of the main reasons why they choose to partner with us.

Increasing throughput. Smaller and smaller structures. More and more cost-effective microchips. BERGHOFF meets the extremely stringent requirements for the mechanical components.

Lighter and lighter. Decreasingly fuel consumption. Increasingly higher payload.

This is how BERGHOFF understands the requirements in the aerospace industry.

Smaller batches, customized compounds and an optimized energy balance. BERGHOFF has been a reliable supplier of ideas in the pump and extruder industry for years.

Reliability, environmental compatibility and economy - for BERGHOFF, these are the most important requirements for gas turbines, steam turbines, generators and large engines.

Access to new resources, the demand for new technologies and that with a focus on sustainable environmental protection. Challenges for which companies count on BERGHOFF.

More flexible and efficient manufacturing solutions are in demand.

BERGHOFF supports its partners in minimizing the development risks of new products.

Strategische Partner von BERGHOFF kommen typischerweise aus hoch anspruchsvollen Branchen und suchen ihrerseits einen Premium-Supplier. BERGHOFF-Kunden zeichnen sich durch überdurchschnittlich hohe Ansprüche an Prozessqualität, Bearbeitungsqualität, Versorgungssicherheit und insbesondere Kommunikationsprozesse aus.

It is precisely the greatest possible reduction in supply risk that is a top priority for BERGHOFF customers and one of the main reasons why they choose to partner with BERGHOFF.

Increasing throughput. Smaller and smaller structures. More and more cost-effective microchips. BERGHOFF meets the extremely stringent requirements for the mechanical components.

Lighter and lighter. Decreasingly fuel consumption. Increasingly higher payload.

This is how BERGHOFF understands the requirements in the aerospace industry.

Access to new resources, the demand for new technologies and that with a focus on sustainable environmental protection. Challenges for which companies count on BERGHOFF.

Our high-performance, state-of-the-art machinery offers best-in-class conditions, such as air conditioning and state-of-the-art testing and cleaning processes.

In doing so, BERGHOFF achieves manufacturing tolerances of the highest precision.

Our high-performance, state-of-the-art machinery offers best-in-class conditions, such as air conditioning and state-of-the-art testing and cleaning processes.

In doing so, BERGHOFF achieves manufacturing tolerances of the highest precision.

Möchten Sie die BERGHOFF Group kennen-lernen, mehr darüber erfahren, wie der 3-Step Vertical Integration Process® Ihren Wett-bewerbsvorsprung ausbauen kann, einen personal appointment or request a very specific offer? Then we look forward to hearing from you.

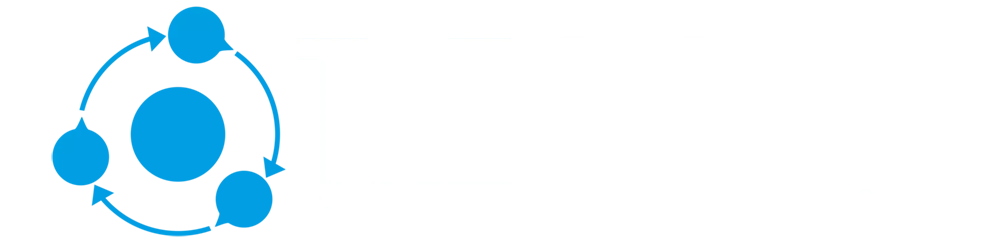

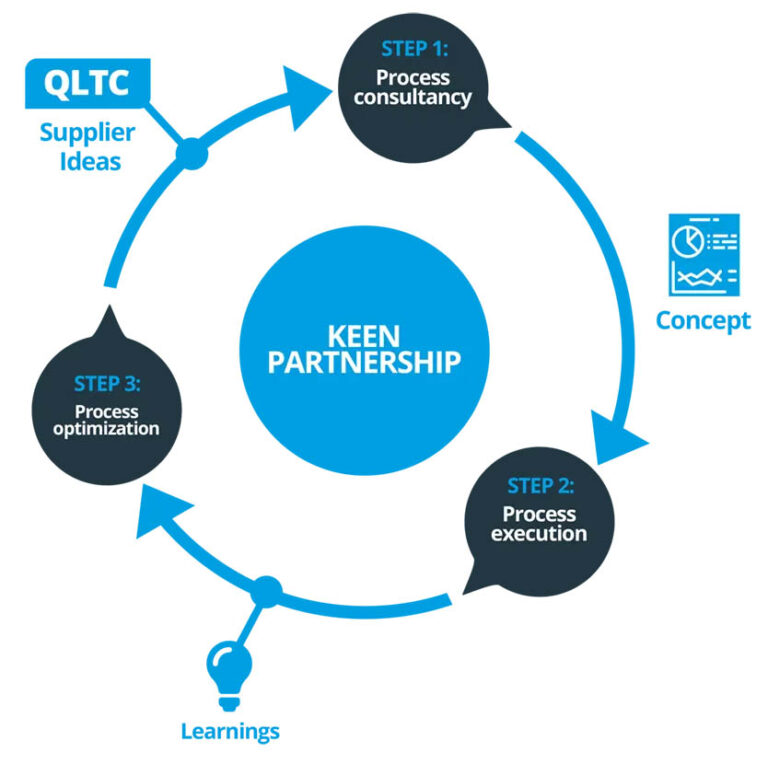

The 3-Step Vertical Integration Process® is the basis for a strategic partnership with our customers and is based on 30 years of experience as an internationally operating world market leader for the mechanical processing of complex metal components as well as cooperation with universities and research institutes in the field of future-oriented production technologies on so-called Supplier Ideas.

Analogous to the approach used in various industries (e.g. construction), the 3-Step Vertical Integration Process® enables a step-by-step realization of your technically demanding project and guarantees the reduction of realization risks.

In addition, you as a customer have the option to commission the actual production of your component freely on the market on the basis of the BERGHOFF planning from STEP 1. If you decide to have your component manufactured by BERGHOFF, services will be credited to the subsequent step and you will receive "Berghoff Supplier Ideas" in order to better position yourself in the market.

Increase in quality in terms of strength, durability, wear and load capacity, among others.

Improving logistics processes by, among other things, reducing lead times, just-in-time supply, optimized lot sizes and ideal number of pieces.

Introducing innovative technologies and processes and constantly reviewing the best machining processes.

Long-term cost reduction through business plans and cost-down road-maps to maintain and improve competitive position.

Certificates prove that companies deliver what they promise. And they prove that companies can meet the highest quality standards and keep getting better.

The companies in the BERGHOFF Group are approved according to one or more of the following certifications:

CEO

CEO

Technical management

Head of QM/ IT

sales and marketing management

personnel management

training management

Central