HALBLEITERINDUSTRIE

Halbleiter- und EUV-Lithographie

Immer höherer Throughput. Immer kleinere Strukturen. Immer kostengünstigere Mikrochips. BERGHOFF erfüllt die extrem strengen Anforderungen an die mechanischen Komponenten.

Herzlich Willkommen bei BERGHOFF

Herzlich Willkommen bei BERGHOFF

Über 40 Jahre Präzision aus Leidenschaft

Bereits seit 40 Jahren vertrauen führende Hightech-Unternehmen aus dem Maschinen- und Anlagenbau BERGHOFF bei der Planung und Fertigung hochkomplexer Bauteile, Baugruppen und Module. Wir erfüllen Ihre allerhöchsten Ansprüche an Qualität und Versorgungssicherheit und unterstützen Sie als strategischer Partner, um in Ihrem Markt Ihre Spitzenposition und Technologieführerschaft weiter auszubauen.

Unsere Überzeugung ist, dass eine Maschine nur dann in herausragender Qualität entsteht, wenn auch jedes einzelne Bauteil diesen Anspruch erfüllt. Dafür bringen wir täglich das Know-How der weltbesten Fertigungsspezialisten und unseren state-of-the-Art-Maschinenpark mit ein. Zuverlässig und in Time, in tausenden erfolgreichen Projekten.

Neben unserer operativen Exzellenz verstehen wir uns vor allem als der Supply-Chain-Partner für mechanische Komplettlösungen in der Value-Chain unserer Kunden. Wir setzen Ihre Ideen flexibel und innovativ von der Projektierung bis zur fertigen Komponente zuverlässig in die Realität um. Alles aus einer Hand. Im Ergebnis realisieren wir für Sie signifikante Skaleneffekte.

Höchste Zuverlässigkeit und Flexibilität

Top-ausgebildete und erfahrene Mitarbeiter sorgen für höchste Prozess- und Bearbeitungsqualität. Unser leistungsstarker state-of-the-Art-Maschinenpark bietet Best-in-Class-Bedingungen wie z.B. Klimatisierung und modernste Prüf- und Reinigungsverfahren.

Dabei erreicht BERGHOFF Fertigungstoleranzen in höchster Präzision. Prototypen und kundenindividuelle Sonderprojekte werden agil in weniger als 4 Wochen realisiert.

Alles aus einer Hand

Unsere Kunden erhalten auf Wunsch über die Fertigung hinaus alle relevanten Schritte ihrer Value-Chain aus einer Hand – Dazu zählen beispielsweise die Materialbeschaffung, unterschiedlichste Dienstleistungen wie Elektronenstrahl-Schweißen, Vakuumlöten oder spezielle Oberflächenveredlung, Reinigung und komplette Montage.

Dabei werden regelmäßig signifikante Kosteneinsparungen und Qualitätsverbesserungen realisiert.

Wir garantieren volle Transparenz für unsere Kunden: Sie wissen zu jeder Zeit und zu jedem Schritt, wie und wo ihr Produkt prozessiert wird.

Innovation und technologischer Fortschritt

Wir arbeiten permanent daran die technologische Führerschaft unserer Kunden weiter auszubauen.

Das Einbringen von hoch innovativen Technologien und Verfahren sowie die ständige Überprüfung und Verbesserung sämtlicher Bearbeitungsprozesse ist fester Bestandteil unseres Arbeitens.

Das Ergebnis ist eine stetige Optimierung auf allen Fertigungsebenen. Die daraus gewonnenen Erkenntnisse geben wir an unseren Kunden weiter.

Seit über 35 Jahren vertrauen führende Hightech-Unternehmen aus dem Maschinen- und Anlagenbau der BERGHOFF bei der Planung und Fertigung hochkomplexer Bauteile, Baugruppen und Module. Wir erfüllen Ihre allerhöchsten Ansprüche an Qualität und Versorgungssicherheit und unterstützen Sie als strategischer Partner, um in Ihrem Markt Ihre Spitzenposition und Technologieführerschaft weiter auszubauen.

Unsere Überzeugung ist, dass eine Maschine nur dann in herausragender Qualität entsteht, wenn auch jedes einzelne Bauteil diesen Anspruch erfüllt. Dafür bringen wir täglich das Know-How der weltbesten Fertigungsspezialisten und unseren state-of-the-Art-Maschinenpark mit ein. Zuverlässig und in Time, in tausenden erfolgreichen Projekten.

Neben unserer operativen Exzellenz verstehen wir uns vor allem als der Supply-Chain-Partner für mechanische Komplettlösungen in der Value-Chain unserer Kunden. Wir setzen Ihre Ideen flexibel und innovativ von der Entwicklung bis zur fertigen Komponente zuverlässig in die Realität um, alles aus einer Hand. Im Ergebnis realisieren wir für Sie signifikante Skaleneffekte.

Strategische Partner von BERGHOFF kommen typischerweise aus hoch anspruchsvollen Branchen und suchen, ihrerseits einen Premium-Supplier. BERGHOFF-Kunden zeichnen sich durch überdurchschnittlich hohe Ansprüche an Prozessqualität, Bearbeitungsqualität, Versorgungssicherheit und insbesondere Kommunikationsprozesse aus.

Gerade die größtmögliche Reduzierung des Versorgungsrisikos hat bei BERGHOFF-Kunden oberste Priorität und ist einer der Hauptgründe, warum sie sich für eine Partnerschaft mit BERGHOFF entscheiden.

Immer höherer Throughput. Immer kleinere Strukturen. Immer kostengünstigere Mikrochips. BERGHOFF erfüllt die extrem strengen Anforderungen an die mechanischen Komponenten.

Immer leichter. Immer weniger Verbrauch. Immer höhere Nutzlast.

So versteht BERGHOFF die Anforderungen in der Luft- und Raumfahrt.

Kleinere Chargen, kundenspezifische Compounds und eine optimierte Energiebilanz. BERGHOFF ist in der Pumpen- und Extruderindustrie seit Jahren ein zuverlässiger Ideenlieferant.

Zuverlässigkeit, Umweltverträglichkeit und Wirtschaftlichkeit – das sind für BERGHOFF die wichtigsten Anforderungen an Gasturbinen, Dampfturbinen, Generatoren und Großmotoren.

Zugang zu neuen Ressourcen, die Nachfrage nach neuen Technologien und das mit dem Schwerpunkt auf nachhaltigen Umweltschutz. Herausforderungen, bei denen Unternehmen auf BERGHOFF zählen.

Flexiblere und effizientere Fertigungslösungen sind gefragt.

BERGHOFF unterstützt seine Partner dabei, die Entwicklungsrisiken neuer Produkte zu minimieren.

Strategische Partner von BERGHOFF kommen typischerweise aus hoch anspruchsvollen Branchen und suchen ihrerseits einen Premium-Supplier. BERGHOFF-Kunden zeichnen sich durch überdurchschnittlich hohe Ansprüche an Prozessqualität, Bearbeitungsqualität, Versorgungssicherheit und insbesondere Kommunikationsprozesse aus.

Gerade die größtmögliche Reduzierung des Versorgungsrisikos hat bei BERGHOFF-Kunden oberste Priorität und ist einer der Hauptgründe, warum sie sich für eine Partnerschaft mit BERGHOFF entscheiden.

Immer höherer Throughput. Immer kleinere Strukturen. Immer kostengünstigere Mikrochips. BERGHOFF erfüllt die extrem strengen Anforderungen an die mechanischen Komponenten.

Immer leichter. Immer weniger Verbrauch. Immer höhere Nutzlast.

So versteht BERGHOFF die Anforderungen in der Luft- und Raumfahrt.

Zugang zu neuen Ressourcen, die Nachfrage nach neuen Technologien und das mit dem Schwerpunkt auf nachhaltigen Umweltschutz. Herausforderungen, bei denen Unternehmen auf BERGHOFF zählen.

Unser leistungsstarker state-of-the-Art Maschinenpark bietet Best-in-Class-Bedingungen wie z.B. Klimatisierung und modernste Prüf- und Reinigungsverfahren.

Dabei erreicht BERGHOFF Fertigungstoleranzen in höchster Präzision.

Unser leistungsstarker state-of-the-Art Maschinenpark bietet Best-in-Class-Bedingungen wie z.B. Klimatisierung und modernste Prüf- und Reinigungsverfahren.

Dabei erreicht BERGHOFF Fertigungstoleranzen in höchster Präzision.

Möchten Sie die BERGHOFF Group kennen-lernen, mehr darüber erfahren, wie der 3-Step Vertical Integration Process® Ihren Wett-bewerbsvorsprung ausbauen kann, einen persönlichen Termin vereinbaren oder ein ganz konkretes Angebot anfordern? Dann freuen wir uns über Ihre Kontaktaufnahme.

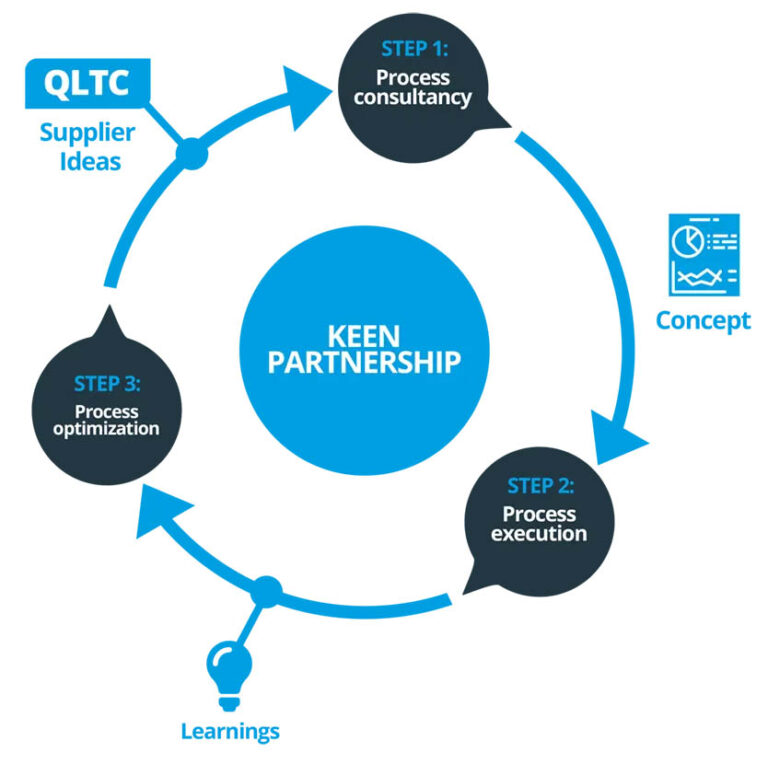

Der 3-Step Vertical Integration Process® ist die Grundlage für eine strategische Partnerschaft mit unseren Kunden und basiert auf der 30-jährigen Erfahrung als international operierender Weltmarktführer für die mechanische Bearbeitung von komplexen Metallbauteilen sowie der Zusammenarbeit mit Universitäten und Forschungseinrichtungen im Bereich zukunftsweisender Produktionstechnologien zu sogenannten Supplier Ideas.

Analog zu der Vorgehensweise aus diversen Branchen (z.B. Baubranche) ermöglicht der 3-Step Vertical Integration Process® eine schrittweise Realisierung Ihres technisch anspruchsvollen Projektes und garantiert die Reduzierung von Realisierungsrisiken.

Darüber hinaus haben Sie als Kunde die Möglichkeit die eigentliche Fertigung Ihres Bauteils frei auf dem Markt auf Basis der BERGHOFF-Planung aus STEP 1 zu beauftragen. Sollten Sie sich für die Realisierung bei BERGHOFF entscheiden, werden Leistungen auf den Folgeschritt angerechnet und Sie erhalten „Berghoff Supplier Ideas“ um sich damit selber am Markt besser zu positionieren.

Erhöhung der Qualität u.a. bezogen auf Festigkeit, Langlebigkeit, Verschleiss und Belastbarkeit.

Verbesserung der Logistikprozesse u.a. durch Verringerung der Durchlaufzeit, Just-in-time-supply, optimierte Losgrößen und ideale Anzahl von Stückzahlen.

Einbringen von innovativen Technologien und Verfahren und ständiges Überprüfen der besten Bearbeitungsprozesse.

Langfristige Kostensenkung durch Businesspläne und Cost-Down-Roadmaps zur Aufrechterhaltung und Verbesserung der Wettbewerbsposition.

Zertifikate beweisen, dass Unternehmen das halten, was sie versprechen. Und sie beweisen, dass Unternehmen sich höchsten Qualitätsansprüchen stellen können und dabei immer besser werden.

Die Unternehmen in der BERGHOFF Group sind nach einer oder mehreren der folgenden Zertifizierungen zugelassen:

Geschäftsführung

geschäftsführung

Technische leitung

Leiter QM/ IT

vertriebs- und marketingleitung

personalleitung

ausbildungsleitung

Zentrale